Industry News

Carbon Fiber Fundamentals

Carbon Fiber belongs to polymer materials, is currently a material in the field of material strength effect of a material, strength of more than 3800MPa, is more than 10 times the strength of ordinary steel, and at the same time has a good conductive, acid and alkali resistance, high temperature resistance, X-ray transmittance, and so many other excellent characteristics of the material. Carbon fiber is mainly composed of carbon elements of a special fiber, its carbon content varies with different types, generally more than 90%.

The specific resistance of carbon fiber is related to the type of fiber, at 25℃, the high modulus is 775, and the high strength carbon fiber is 1500 per centimeter. this makes carbon fiber has effectively high specific strength and specific modulus among all high performance fibers. Compared with titanium, steel, aluminum and other metal materials, carbon fiber in physical properties with high strength, high modulus, low density, low coefficient of linear expansion, etc., can be called the king of new materials.

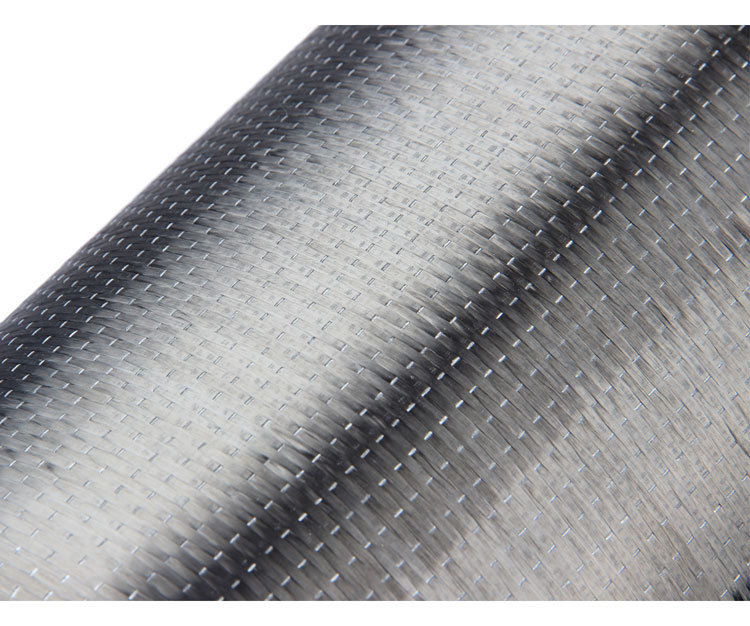

Carbon fiber in addition to the general characteristics of carbon materials, carbon fiber woven cloth has a significant anisotropic soft shape, can be processed into a variety of fabrics, and because of the small specific gravity, along the fiber axis shows high strength, carbon fiber reinforced epoxy resin composite materials, its specific strength, specific modulus of the comprehensive indicators, in the existing structural materials is the effect of high.

Carbon fiber also has excellent fiber (one of the expression of fiber is 9000 meters long fiber grams), generally only about 19 grams, tensile strength up to 300kg per micron. Few other materials have as wide a range of excellent properties as carbon fiber, so it is used in areas where there are strict requirements for purpose, stiffness, weight, and fatigue properties. In the absence of contact with air and oxidants, carbon fiber can withstand high temperatures of more than 3,000 degrees Celsius, with outstanding heat-resistant properties, compared with other materials, carbon fiber temperature higher than 1,500 ℃ when the strength begins to decline, and the higher the temperature, the greater the decline in fiber strength. Carbon fiber radial strength is not as strong as axial strength, thus carbon fiber taboo radial strength (i.e., can not tie) and other materials whisker performance has long been greatly reduced. In addition, carbon fiber also has good low-temperature resistance, such as liquid nitrogen temperature is not brittle.

Uses The composite material combined by carbon fiber and epoxy resin has become an advanced aerospace material due to its small specific gravity, good rigidity and high strength. Because every 1 kilogram reduction in the weight of the space vehicle can make the launch vehicle 500 kilograms lighter. Therefore, there is a competition to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, it uses the carbon fiber composite material has accounted for the weight of the whole machine 1/4, accounting for the weight of the wing 1/3. It is reported that the United States space shuttle on the key components of the three rocket propellers as well as advanced MX missile launch tubes, etc., are made of advanced carbon fiber composite materials.

Nowadays, the F1 (World Class 1 Equation Championship) racing car, most of the structure of the body is made of carbon fiber. A major selling point of supercars is also the use of carbon fiber around the body to improve aerodynamics and structural strength. Carbon fiber can be processed into fabrics, mats, mats, tapes, paper and other materials. In addition to the traditional use of carbon fiber as insulation materials, generally not used alone, more as reinforcing materials added to the resin, metal, ceramics, concrete and other materials, constituting a composite material. Carbon fiber reinforced composite materials can be used as aircraft structural materials, electromagnetic shielding in addition to electrical materials, artificial ligaments and other body substitute materials, as well as for the manufacture of rocket shells, motorized boats, industrial robots, automotive leaf springs and drive shafts.

RELATED NEWS

- Composite Laminate Cutting 2024-08-23

- Composite Fabric Weave Styles 2021-01-31

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kai Liu

Phone: +86-15376801419

E-mail: liukai@hxcomposite.com

Whatsapp:+86-153 7680 1419

Add: D-407 Yintaicheng, Zhangdian, Zibo, Shandong 255000